WANHAO is the name to trust for reliable CNC machining services in precision machining. Our team has years of experience working with customers of all sizes and provides products that exceed your expectations. With WANHAO, you can be assured of only top-quality products that are expertly manufactured with only your requirements in mind. It’s time to find where to find reliable CNC machining services and learn the advantages of CNC machining in precision parts.

Advantages of CNC Machining for Your Manufacturing Process One of the main advantages is its accuracy. CNC machines can also do intricate cuts and shapes – they will always produce the part to exact specifications. This accuracy minimizes mistakes and waste, resulting in cost savings and enhanced productivity. With CNC being faster than traditional machining processes, you can keep up with tight deadlines and get products out on time. The automatic element of CNC machinery also means there is less reliance on manpower, so workers can concentrate on other tasks in the production process. Ultimately, the utilization of CNC machining can help simplify production efforts, improve quality control standards, and ultimately lead to higher productivity.

High-precision machine tools are essential to produce complex components While working on that, the need for high precision machining processes ensures us the results we want. One such method is multi-axis machining, whereby CNC machines could move simultaneously in multiple directions and achieve detailed cuts over intricate parts. Another method, high-speed machining, uses techniques related to those of the above but applied on more difficult materials. For close tolerance fit components, for example, honing and lapping processes can be employed to put final surface finishes on the components and achieve appropriate fit and function. That is why Wire EDM (Electrical Discharge Machining) even though it may take longer and more costly than conventional cutting methods, the wire EDM technique yields a precision cut that can be used on fragile and detailed pieces. With these precision machining methods, manufacturers are able to create intricate parts with a higher level of accuracy and quality, all while addressing the demands of today’s competitive marketplace.

WANHAO which provides high-quality CNC machining services to customers in the global market. Our machinery is second to none and our experienced technicians are dedicated to quality work in every job we do. We specialize in the rapid turnaround of high-end products to ensure maximum performance for our customers. It's our commitment to quality and service that make us stand out from other CNC machine shops.

If you choose WANHAO for your CNC machining projects, you will receive a number of advantages. CNC Machined Components – Some of the Key Benefits Precision: One of the top benefits that come with using CNC machining is the precision and accuracy that it guarantees. This enables us to design the most complex patterns, intricate designs, and the highest degree of detail in molds, at a minimum cost thus giving you value for your investment. Moreover, CNC machining is a cost-effective solution since it requires less labor force and generates less waste material. Through WANHAO's CNC Machining Service, we are striving to achieve these three things as well: high-quality components, quick communication on your project through our standards, and favorable cost savings for your projects.

The company has been Cnc machining precision machining ISO9001 certification. The production of products will go through the initial inspection and reinspection and the final inspection, which is triple inspection, in the extent it is feasible to ensure quality, to provide customers with the best experience.

Yunlong Wanhao Cnc machining precision machining has been established for more than 21 years. It provides large corporations all year long, and is proficient in the production of machining.

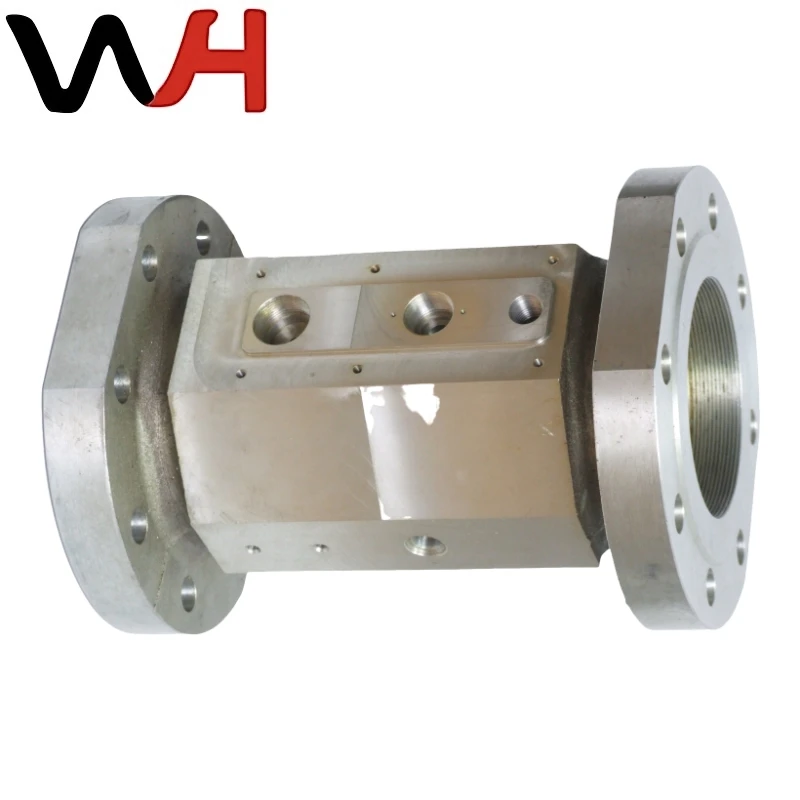

The principal Cnc machining precision machining of the company is forging and casting. The main production of various auto parts, fasteners can be customized according to specifications of the customers.

Cnc machining precision machining and high-quality delivery to every client.