Material |

Stainless steel: 302, 303, 304, 316, 420 etc. Alloy steel: 40Cr, 42CrMo, 35CrMo Carbon steel: Q235, Q345E 20#, 45# etc. Aluminum: 6061-T6, 6063, 7075-T6, 5052 etc. Copper: Brass, Copper, Bronze etc |

Main Process |

CNC Turning, Milling, drilling, auto lathe, tapping, bushing, forging, Metal stamping, cold extrusion, welding, metal mold design and manufacture,etc |

Surface treatment |

Nickel plated, chrome, Galvanized, Silver, gold plating; Black oxide coating; polishing; Transparent, Color anodized; Hard anodizing; Powder coating; Sand blasting, Laser carving, Silk screening; etc |

Main Equipment |

CNC machining, CNC turning, CNC milling, CNC lathe processing, CNC Boring, CNC grinding, CNC drilling etc |

Package |

1)Standard packaging,2) Pallet or container, 3) According to customized specifications |

Testing Equipment |

3D Coordinate measuring machineCMM,Hardness instrument |

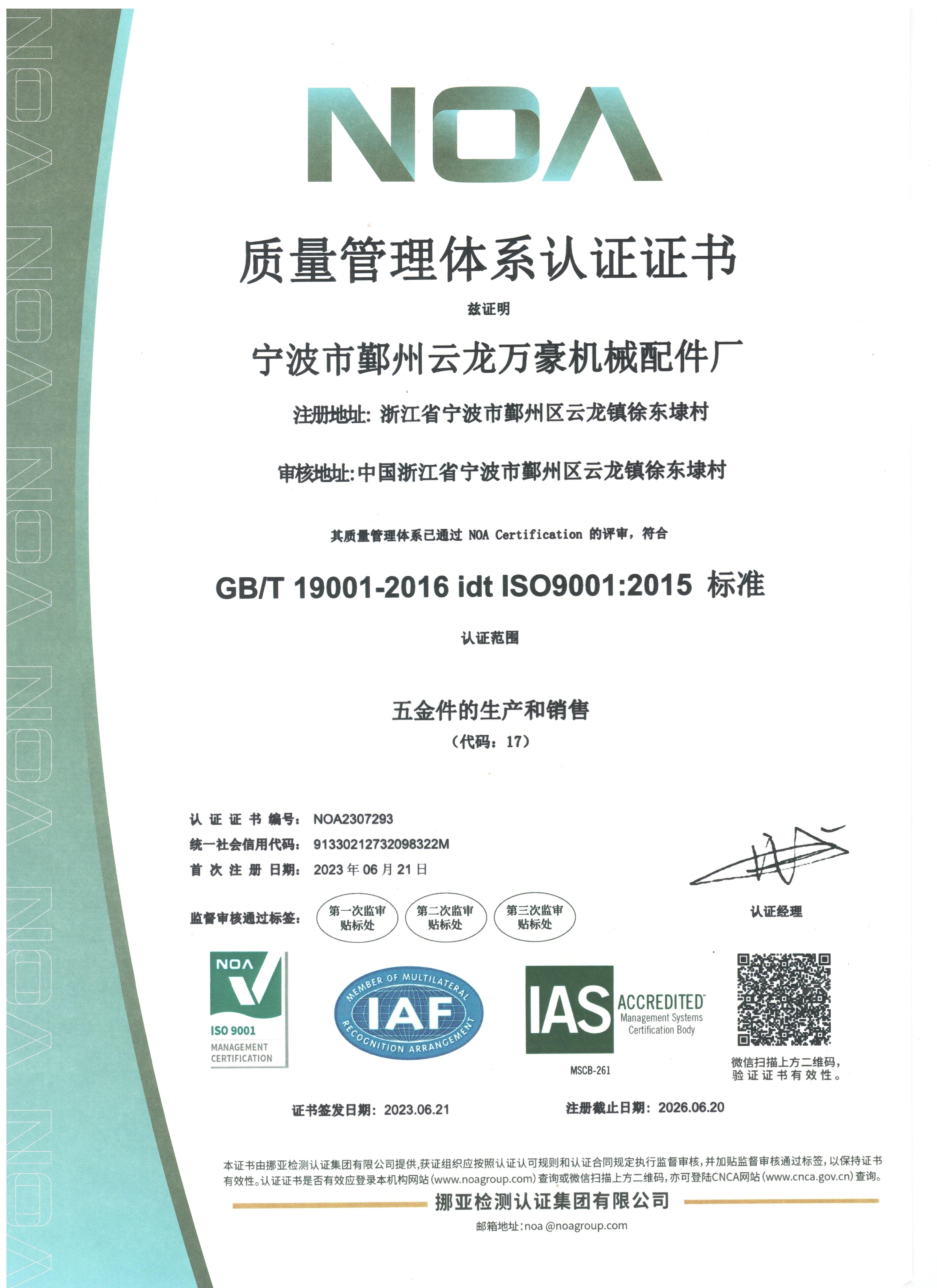

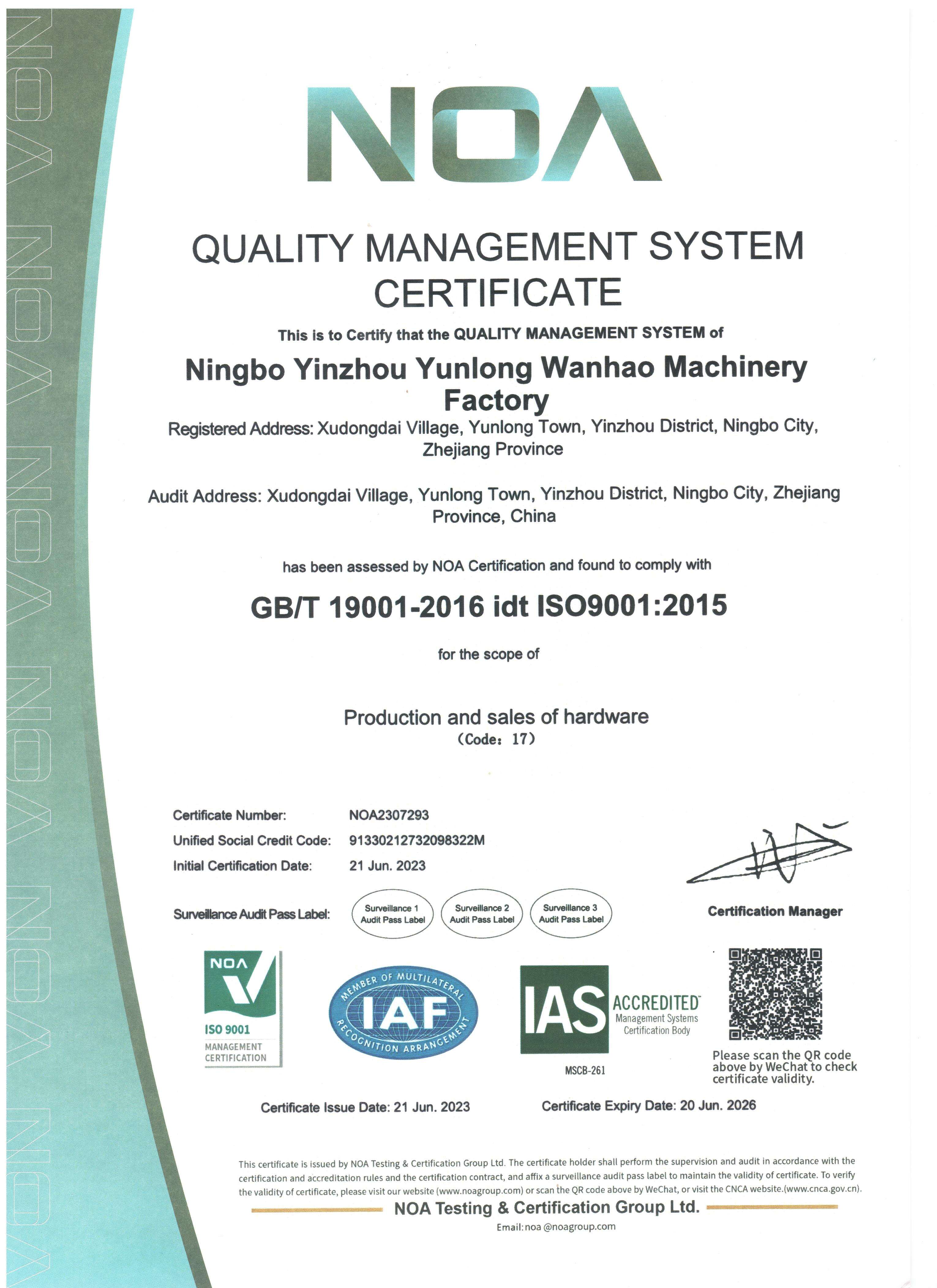

Certificate |

ISO 9001: 2015 |

Shipping Ways |

Express DHL, Fedex, UPS, TNT, EMS; By air; By sea; Or according to your requirements |

YUNLONG

A leading brand in the manufacturing of precision stainless steel hot forging parts, hot forging press parts, and other metal forged parts. With several years of experience in the industry, we are proud to provide top-quality services and products and customer support that is exceptional. Made using the quality materials which are greatest and technology in the market. We use the latest methods that are forging create components that are strong, durable, and dependable. Our hot press that is forging are ideal for use in an array of industries, including automotive, aerospace, and army. Along with our stainless forging capabilities, we additionally provide brass, copper, and aluminum hot forging. We of skilled professionals gets the expertise and knowledge to produce steel that is top-quality parts for any application. We can provide high-volume manufacturing runs to generally meet your needs whether you need tiny or big parts. At YUNLONG, we pride ourselves on providing customer service that is exceptional. Our team of experts is always available to answer your questions and supply you because of the guidance you need to make informed decisions about your hot forging needs. We work closely with our clients to make sure that their needs are met and that their expectations are surpassed. Contact us today to see how we can meet your hot forging needs.

Our friendly team would love to hear from you!