Vous vous êtes déjà demandé comment les objets métalliques sont fabriqués ? Le moulage sous pression : un procédé spécial pour fabriquer de nombreuses choses, y compris des pièces automobiles, des jouets et des ustensiles de cuisine que vous utilisez tous les jours. Le moulage sous pression consiste à verser du métal fondu dans le moule et à le laisser refroidir en durcissant. Cela nous permet de former des pièces métalliques durables et utiles.

Tout d'abord, un moule doit être créé pour l'objet que vous souhaitez obtenir par fonderie sous pression. Ce type de moule, qui se compose généralement de deux parties, s'ajuste étroitement l'une à l'autre. Une fois le moule préparé, la température de ce moulin dépasse 2000 degrés F. Ce processus de chauffage est crucial car il empêche le métal de fondre et de détruire sa forme lorsqu'il est versé dans le moule. Lorsque le moule a atteint une température appropriée, ils y ajoutent soigneusement du métal liquide et le laissent refroidir. Lorsque le métal refroidit, il se contracte pour prendre la forme finale définie par des moules rigides aux dimensions de haute précision.

Qu'est-ce qui est si bien avec la fonderie sous pression ? Elle permet de produire de nombreuses copies de la même chose, très rapidement. Si vous devez fabriquer beaucoup de pièces identiques, c'est extrêmement utile. En ce qui concerne la fonderie sous pression, comme ses moules sont créés en injectant du métal fondu à haute pression, les objets produits nécessitent généralement peu de finition post-production. Par conséquent, les fabricants peuvent économiser du temps et de leurs ressources.

Non seulement cela, mais il peut générer des formes extrêmement complexes que de nombreuses autres techniques auraient du mal à créer. Un moulage détaillé et de petites pièces peuvent être inclus avec les objets fabriqués, grâce à ces moules précis. En conséquence, l'aluminium coulé sous pression est utilisé fréquemment car il fournit des pièces qui ne parlent pas seulement en fonction des dégagements (par exemple - des engrenages à utiliser dans une montre), mais aussi mouvement et interaction avec d'autres actions (comme par exemple - des parties téga). Quelles formes doivent être produites est un facteur déterminant pour choisir quel type de technologie de fabrication est suffisamment avancé.

La fonderie sous pression peut également fournir des pièces très petites en plus de formes complexes. Elles peuvent être minuscules, au point qu'elles peuvent fabriquer des pièces de seulement quelques millimètres. Cela est avantageux dans plusieurs industries où il est nécessaire d'avoir des pièces petites et précises, comme l'électronique ou les dispositifs médicaux. Un autre avantage de la fonderie sous pression est la capacité de produire ces petits composants.

De nombreuses autres industries dépendent de la fonderie sous pression. En réalité, de nombreux produits que nous utilisons quotidiennement n'auraient pas été possibles sans la fonderie sous pression. Des pièces automobiles, des composants d'avion, des jouets, des outils de cuisine aux ordinateurs, ce sont là quelques-uns des produits qui utilisent la fonderie sous pression. Vous rencontrez des pièces en fonderie sous pression dans de nombreux aspects de votre vie... Elles sont souvent invisibles, mais cela souligne simplement le fait que ces petites choses offrent un confort et une commodité que vous n'auriez jamais eus auparavant.

Le moulage sous pression est essentiel pour plusieurs raisons, y compris le fait qu'il permet de produire des composants ayant une forme plus complexe et une finition de surface brute. Une telle précision est essentielle dans des industries comme l'aéronautique et la fabrication automobile, où la sécurité et la fiabilité sont cruciales. Lorsque vous pensez aux voitures ou aux avions, ne voulez-vous pas que chaque pièce soit fabriquée correctement pour que les gens restent en sécurité ?

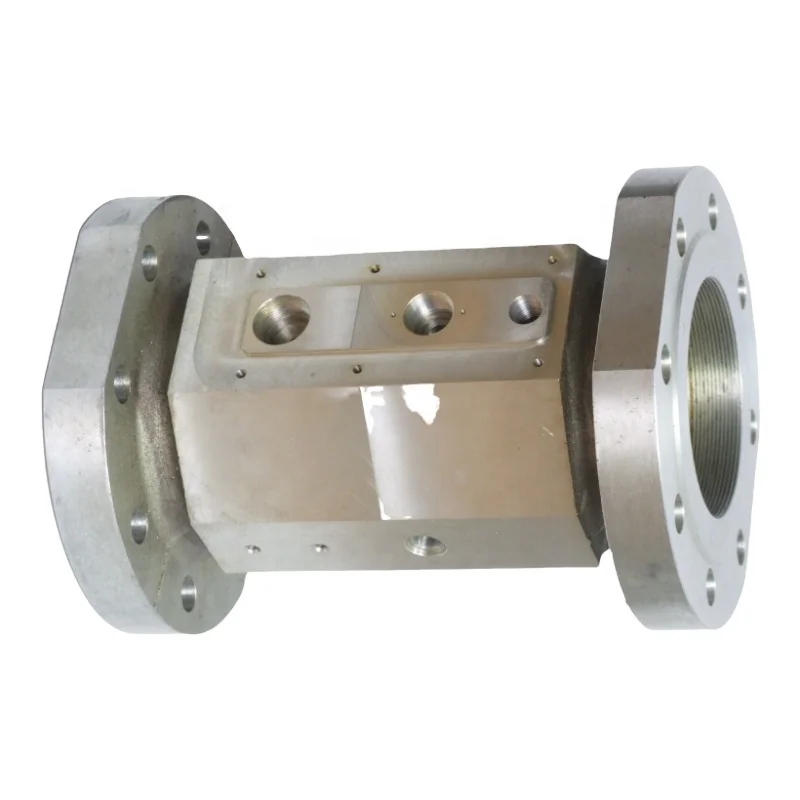

Entreprise de moulage sous pression spécialisée principalement dans la fabrication de composants moulés et de pièces forgées. Les pièces détachées automobiles sur mesure et les éléments de fixation constituent ses principaux produits.

Yunlong Wanhao Machinery est une entreprise fondée il y a plus de 21 ans, disponible toute l'année, qui fournit diverses grandes entreprises, avec une expertise en injecto-moulage dans la production de machines, capable de répondre aux besoins de ses clients.

Moulage sous pression, livraison de haute qualité à chaque client.

L'entreprise détient la certification ISO 9001 pour le moulage sous pression. La production des articles fait l'objet d'une inspection initiale, d'une contre-inspection et d'une inspection finale (triple inspection), dans toute la mesure du possible, afin de garantir la qualité optimale des produits et d'offrir aux clients une expérience des plus agréables.